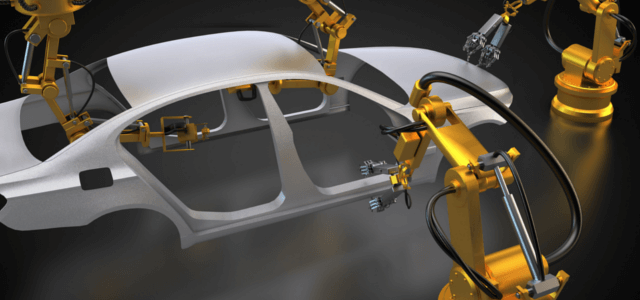

In industrial facilities, motors are the workhorses driving essential equipment like pumps, conveyors, and compressors. But here’s the thing—many businesses don’t realize how much energy is wasted when motors are not properly sized. Using a too-big or small motor isn’t just inefficient; it can lead to higher energy bills, frequent breakdowns, and costly maintenance.

Think of it like using a race car to drive through a crowded city or a bicycle to carry heavy cargo. Neither scenario works well; the same goes for mismatched motors in your operations. Right motor sizing ensures your equipment performs well while saving energy and money.

In this post, we’ll explore why getting motor sizing right is critical, the risks of improper sizing, and how to achieve efficiency and performance in your facility. Let’s dive in!

Consequences of Oversized Motors

Using motors that are too large for a given application is a common mistake in industrial settings. Oversized motors often run below their full load capacity, which leads to inefficiencies. When a motor operates far below its optimal load, it uses more energy than necessary to complete the task.

This inefficiency doesn’t just increase energy bills; it can also lead to higher maintenance costs. Oversized motors generate excessive heat, wear out components faster, and require more frequent servicing. Additionally, the upfront cost of purchasing a larger motor is higher, making oversizing an expensive mistake.

Risks of Undersized Motors

On the other hand, using a motor that is too small for the load can have equally serious consequences. Undersized motors often operate beyond capacity, leading to overheating and excessive wear. This stresses the motor’s components, resulting in frequent breakdowns and reduced lifespan.

When motors fail unexpectedly, the downtime can disrupt operations, leading to production delays and increased costs. For example, if a motor driving a conveyor system breaks down, it can halt an entire assembly line. These disruptions can be costly for industrial facilities that depend on continuous operations.

Steps to Properly Size Motors

Several factors need to be considered before choosing the correct motor size. Here are some of these steps to ensure the best fit:

Analyze the Load: Understand the characteristics of the load, such as whether it’s continuous, variable, or peak.

Determine Torque and Speed: Identify the required torque and speed for the application.

Consider Environmental Conditions: Consider factors like temperature, altitude, and duty cycle, which can affect motor performance.

Select the Motor: Match the motor’s specifications to the operational requirements.

Once you’ve determined the accurate size for a motor, the next step is finding a reputable electric motor seller. Errors in sizing an AC motor or DC motor can lead to overheating, inefficiency, or unnecessary energy waste in industrial systems. So, always look for a supplier with a strong track record, a wide range of motor options, and knowledgeable staff who can guide you in making the best choice.

Reputable sellers also offer warranties, after-sales service, and access to replacement parts, ensuring your investment is protected. Remember to check for customer reviews and certifications to confirm their credibility. Partnering with the right seller can make all the difference in ensuring your motors deliver optimal performance and longevity for your operations.

Benefits of Choosing the Right Size Motor

Here are the key benefits of choosing the right size motor:

Improved Energy Efficiency

A properly sized motor operates within its optimal load range, consuming only the required energy. This reduces energy waste and lowers electricity bills. For example, motors running at their intended capacity often achieve 85-95% efficiency, significantly cutting operating costs.

Enhanced Equipment Longevity

Using the correct motor size minimizes wear and tear. Oversized motors experience low-load inefficiencies, while undersized ones overheat and strain under pressure. Proper sizing ensures the motor runs smoothly, extending its lifespan and reducing maintenance needs.

Lower Maintenance Costs

Right-sized motors reduce the likelihood of breakdowns caused by overloading or underuse. This leads to fewer repairs, lower maintenance costs, and less downtime, allowing for consistent and reliable operations.

Optimised System Performance

The correct motor size ensures seamless operation by matching the load requirements perfectly. This enhances the performance of connected equipment, whether it’s pumps, conveyors, or compressors, improving overall productivity.

Cost Savings

Beyond energy savings, right-sized motors help avoid over-investment in larger motors or replace smaller, overloaded ones frequently. These savings add up, providing a better return on investment over time.

Conclusion

Now that you know the importance of sizing in a motor correctly, it’s clear how much impact this decision has on energy efficiency, operational reliability, and cost savings. So, choose the right motor size. By getting it right, you’re investing in long-term efficiency and sustainable growth for your operations.